Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat:+86 13292778366 / +86 13120261777

Measures to Avoid End-warping of 3PE Anticorrosive Coating of Steel Pipe

Polyethylene (3PE) anticorrosive coating with three-layer structure has been widely used in the oil pipeline industry due to its good corrosion resistance, water vapor permeability resistance and mechanical properties. This kind of anticorrosive layer steel pipe end is prone to the problem of warping due to corrosion.

The analysis shows that when the polyethylene layer groove of the reserved section of 3PE anti-corrosion layer steel pipe is polished, the residual height of the pipe end weld is not polished or the grinding is uneven, which will cause the epoxy powder at the polyethylene bottom of the protruding part of the weld to be worn off. Under the condition that the anti-corrosion pipe is stacked in the open air for a long time, the metal on the weld surface will be corroded first, resulting in the edge warping of 3PE anti-corrosion layer.

The measures to avoid warping at the pipe end of 3PE anti-corrosion layer are:

1. Under the condition of not affecting the pipe mouth welding, the reserved length of epoxy powder at the end of polyethylene layer should be appropriately increased to prevent 3PE anti-corrosion edge warping caused by long steel pipe stacking time and serious metal corrosion at the pipe end.

2. When the anti-corrosion pipe is stacked in the open air for a long time, the pipe end should be covered to prevent rain erosion and cause serious corrosion of the pipe end.

3. If the on-site construction period of the pipeline is long, weldable anti-rust paint can be painted on the exposed part of the pipe end metal to prevent the 3PE anti-corrosion layer from warping due to corrosion during the storage period of the anti-corrosion pipe.

4. Strictly control the grinding quality of weld residual height at the reserved pipe end. Outside the polyethylene groove at the weld seam and other parts of the pipe body, keep the epoxy powder with a length of> 20mm to prevent the bottom of the epoxy powder at the weld seam from corroding first and causing the 3PE anti-corrosion layer to warp. Pay attention:

1) From the beginning of weld grinding to the polyethylene chamfer, there shall be a 10-20mm flat section of polyethylene layer with no weld surplus height as the pipe body, and the polyethylene groove at the pipe end shall be squeezed and bonded.

2) The residual height of the weld after grinding should be flush with the pipe body as far as possible, and there should be no obvious residual height, so as to prevent the epoxy powder from being polished together when the polyethylene layer chamfer is polished.

3) The chamfering of the unground top of the weld and the transition section at the ground shall also be the same as the chamfering of the polyethylene layer (≤ 30 °), so that the squeezing force of the squeezing roller can evenly press on the polyethylene layer and prevent the polyethylene layer from warping due to poor adhesion of the anticorrosive layer at the groove.

Key words:

RELEVANT INFORMATION

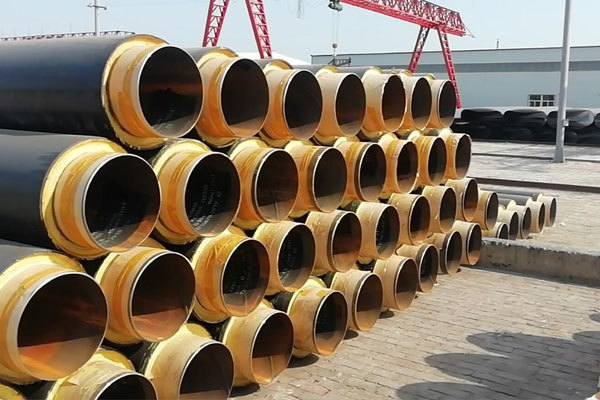

Installation principle of steel insulation pipe

2023-07-26

2023-07-26

Measures to Avoid End-warping of 3PE Anticorrosive Coating of Steel Pipe

2023-07-26