Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat:+86 13292778366 / +86 13120261777

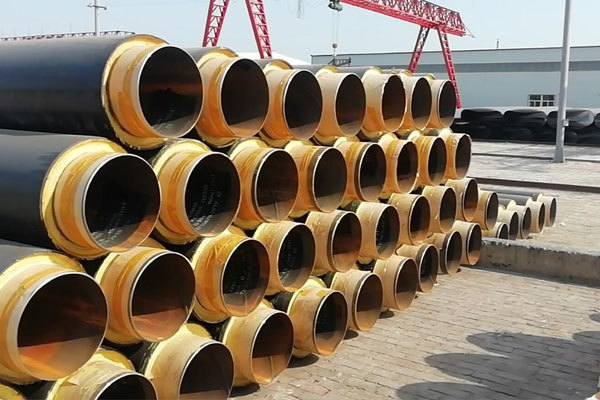

Installation principle of steel insulation pipe

The installation principle of steel sleeve steel insulation pipe: first large and then small; first responsible, then branch; first rise, then fall.

Technical requirements for installation of steel insulated pipe

Basic requirements for installation technology of 1. steel jacket steel insulation pipe

1. Strictly implement the construction pipeline quality acceptance specifications.

2. Before the pipeline is installed, carefully check whether the specifications, materials and design of the pipeline meet the requirements, and carry out rust removal, paint, pipeline dirt and rust removal in accordance with regulations.

3. The installation principle of steel sleeve steel insulation pipe: first large and then small; first responsible, then branch; first rise, then fall.

4. The zui low point of the water system is equipped with a drain valve, and the high point is equipped with an automatic drain valve.

5. Pipeline installation should follow the principle of "large, small, first up, then down, first out.

6. After the pipeline installation is completed, the hydraulic test shall be carried out according to the design requirements.

Welding method of 2. steel sheath steel insulation pipe

1. On the basis of laying and marking, welded pipe construction shall be carried out according to the procedures of rectifying pipe material, cutting material, groove, grouping, welding and slag removal.

2. Groove processing cleaning: the general use of oxygen acetylene flame cutting and gas cutting should be used to cut the groove pipe, and the nozzle with a file for cleaning. Try to cut small diameter pipe with grinding wheel. Oil, rust and water within 20mm on both sides of the inclined plane, metallic luster of the inclined plane, surface defects of the inclined plane, inside and outside of the inclined plane.

3. The welding rod and flux should be dried according to the instructions before use, and kept dry during use.

4. Welding construction shall be carried out in strict accordance with the welding operation instruction. The welding equipment must be inspected before use. Unqualified equipment is strictly prohibited from entering the construction site. Self-inspection and mutual inspection shall be carried out during welding to control welding quality.

Key words:

RELEVANT INFORMATION

Installation principle of steel insulation pipe

2023-07-26

2023-07-26

Measures to Avoid End-warping of 3PE Anticorrosive Coating of Steel Pipe

2023-07-26