Welcome To Know Our Products, We Can Offer You High Quality Products!

WhatsApp / WeChat:+86 13292778366 / +86 13120261777

Introduction of 5 Kinds of Coloring Methods for Anticorrosive Steel Pipe

Introduction of 5 Kinds of Coloring Methods for Anticorrosive Steel Pipe

Anticorrosive steel pipe surface mirror bright treatment method: according to the complexity of anticorrosive steel pipe products and user requirements can be used respectively mechanical polishing, chemical polishing, electrochemical polishing and other methods to achieve mirror gloss. Anticorrosive steel pipe coloring methods are as follows:

1: chemical oxidation coloring method; that is, in a specific solution, the color of the film is formed by chemical oxidation, including dichromate method, mixed sodium salt method, vulcanization method, acid oxidation method and alkaline oxidation method. Generally, the "Yinke method" (INCO) is used more, but if you want to ensure that a batch of products are consistent in color, you must use a reference electrode to control.

2: Electrochemical oxidation coloring method; It is the color of the film formed by electrochemical oxidation in a specific solution.

3: ion deposition oxide coloring method; that is, the stainless steel workpiece is placed in a vacuum coating machine for vacuum evaporation plating. For example: titanium-plated watch case, watch band, generally golden yellow. This method is suitable for high-volume product processing. Because of the large investment and high cost, small batch products are uneconomical.

4: high temperature oxidation coloring method; is in a specific molten salt, immersed in the workpiece to maintain a certain process parameters, so that the workpiece to form a certain thickness of the oxide film, and showing a variety of different colors.

5: gas phase pyrolysis coloring method. More complex, less application in industry.

Key words:

RELEVANT INFORMATION

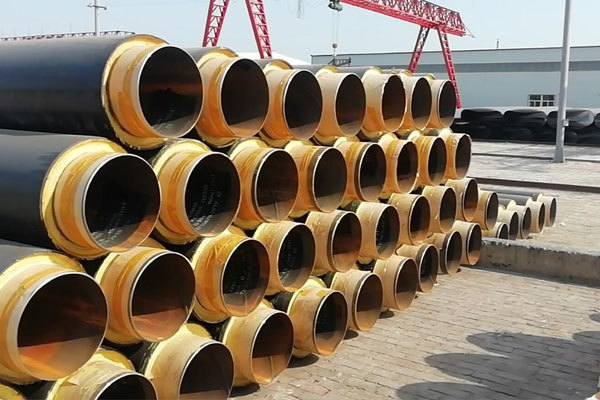

Installation principle of steel insulation pipe

2023-07-26

2023-07-26

Measures to Avoid End-warping of 3PE Anticorrosive Coating of Steel Pipe

2023-07-26